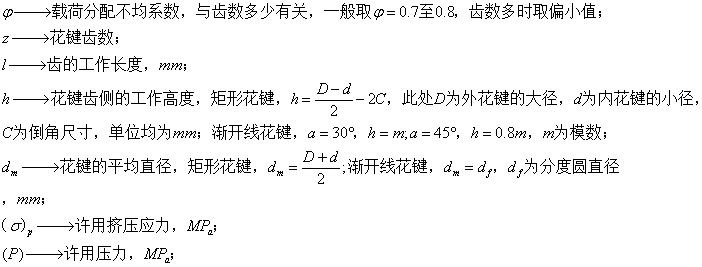

Industry news|2022-03-03| admin

1. The spline connection is composed of a plurality of teeth and keyways, which are evenly distributed on the circumference of the shaft and the hub hole. The flank of the spline is the working surface. Spline connection is suitable for static and dynamic connection.

The main advantages of spline connection are: the number of teeth is large and the force is uniform, so the bearing capacity is high; the groove is shallow, the stress concentration of the tooth root is small, the strength of the shaft and the pivot is weakened, and the parts on the shaft and the shaft are well aligned; Good orientation. The disadvantage is that special equipment is required for processing, and the cost is high.

1. Types and characteristics of splines

The splines have been standardized and can be divided into rectangular splines and involute splines according to the profile tooth shape. The dimensions, tolerances and fit of this spline can be found in the relevant standards respectively.

Rectangular splines and rectangular splines are easy to process, and the grinding method has high precision. , so it is commonly used. Rectangular splines have two size series specified in the standard, namely light series and medium series. The light series has a smaller bearing capacity and is mostly used for static connections with light loads.

Rectangular splines are centered on the minor diameter in the coupling. Both shaft and hub centering surfaces are ground after heat treatment

2. Involute spline, the tooth profile of involute spline is involute. Compared with the rectangular spline, the involute spline has the following characteristics: the tooth root is thicker, the tooth root fillet is larger, and the stress concentration is smaller, so the connection strength is higher and the service life is longer; various processing methods for processing gears can be used. The involute spline is processed, so the manufacturability is better; when the size is small, the manufacturing cost of the broach for processing the spline hole is high, thus limiting its use. The involute spline is centered according to the tooth shape and has the function of automatic centering. It is suitable for connections with larger cores, higher centering accuracy and larger dimensions.

The pressure angle of the involute spline on the index circle is 30°; the other is that the pressure angle of the spline shaft on the index circle is 45°. The involute spline with a pressure angle of 45° has a blunt and short tooth shape, so the weakening of the coupling is small, but the working surface height of the tooth is small, so the bearing capacity is low, multi-purpose and light load, diameter Smaller static joins.

2. Strength calculation of spline connection

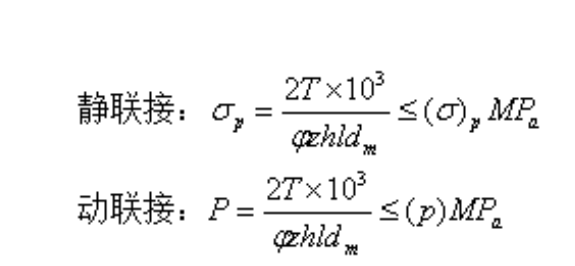

The strength calculation of spline connection is similar to that of key connection. First, according to the structural characteristics of the connection, use requirements and working conditions, select the spline type and size, and then perform the necessary strength check calculation. The main failure form is that the working face is crushed (static connection) or excessive wear (dynamic connection). Therefore, the strength of static connection is usually calculated according to the extrusion stress on the working surface, and the conditional strength of dynamic connection is calculated according to the pressure on the working surface.

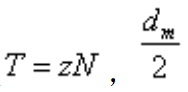

During the calculation, it is assumed that the load is uniformly distributed on the working surface of the key, the resultant force N of the pressure on each tooth surface acts at the average diameter of![]() , that is, the transmitted torque is

, that is, the transmitted torque is , and the coefficient φ is introduced to consider the actual load at The influence of uneven distribution on each spline tooth, the strength condition of the spline connection is:

, and the coefficient φ is introduced to consider the actual load at The influence of uneven distribution on each spline tooth, the strength condition of the spline connection is:

where: